Skiservice

What are the benefits of PRO technology?

PRO technology for stone grinding

With this new development, the removal is controlled even more finely according to the ski geometry. The high-precision pressure curve produces excellent structural results while being gentle on the stone by individually controlling the contact pressure on the running surface from both above and below the stone. This technology is only available from MONTANA in a series machine.

With the PRO technology, the harmonic movement that you also have when skiing is taken into the grinding: The ski glides over the stone as if skiing over a hill. Likewise, the grinding of the shovel and the ski end is thus possible. The PRO technology brings a fiber-free, absolutely flat ground and structured running surface.

First, the base and edge are brought to one level to create the basis for an optimal edge angle. Then, the base is textured to provide optimal glide depending on snow conditions. With this development, the removal is controlled even more precisely. It also makes it possible to grind the shovel and the end of the ski. The structural results are excellent.

Advantages of PRO technology

- High-precision power curve for all ski models

- Through NC technology separately for each stone individually and finely adjustable

- Ski: Twin tip, rocker, freeride and boards, Grinding from shovel to ski end possible

- More accurate and better grinding performance over the whole ski length

- The stone grinding process is performed very harmoniously

Stone force curve

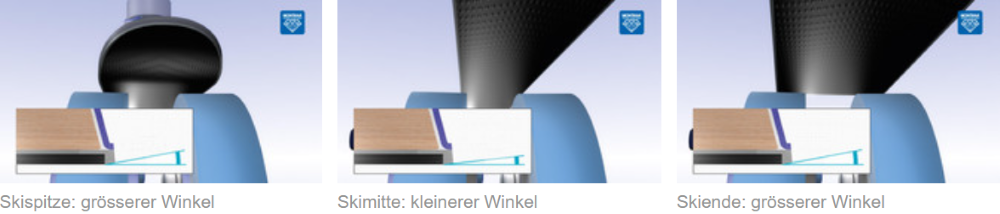

For an even and gentle stone grinding, a different contact pressure can be selected for each of 10 segments of the sports equipment. The force curve can also be varied depending on the direction of processing.

PRO technology - also for tuning

The electronically controlled force curve enables precisely defined tuning over the grinding point.

What is RACE EDGE?

RACE EDGE technology - for the perfect race grind

The unit has been developed for the perfect race grind of the side edges. The side edge prepared at 15,000 rpm and with pressure curve inspires all winter sports enthusiasts who have the highest demands.

Advantages of RACE EDGE technology

- Ridge-free finish

- Ski comes out of the machine ready to race

- Angle adjustment in 0.5° steps

- Functional points of the ski are also optimized

- Uniform grinding pattern

- Speed 15.000 rpm

- Programmable closing time

- Electronically controlled pressure curves for a precisely defined grinding pressure at the grinding point

What is GRIPtech?

GRIPTECH - the revolution in side edge preparation

With the MONTANA GRIPtech system, grinding takes place in the vertical direction. This creates a precise, sharp and longlife edge. The sports equipment is ground gently over all functionalpoints from start to finish in RACE EDGE quality without running-in marks.

Advantages of GRIPtech:

- Exact and uniform angle

- Excellent surface in RACE EDGE quality

- Grounds all function points from the shovel to the end of the ski

- Highest lifetime of the sharpening

- Gentle removal of material

- Highest throughput with constant quality

- Grounds even corrod edges protruding

- High economy

- For ski and snowboard

- Maximum riding pleasure

How does the ski and board service with MONTANA machines work?

Your ski is prepared on high precision equipment from MONTANA in 5 steps

1. base repair

We recommend the base melting machines P-TEX MASTER or MRS. Both machines allow positive melting of the base damage and high throughput for ski and snowboard. For a manual repair, the MONTY extruder is used.

2. Tread stone grinding

First, the base and edge are brought to a level to create the basis for an optimal edge angle. Then the base is textured for optimum glide, depending on snow conditions. The MONTANA structure system can be used to create a wide variety of structures: from simple linear structures to complex, computer-controlled VARIO structures for racing ski preparation in the World Cup. The MONTANA stone grinding is characterized by the absolutely fiber-free grinding of the running surface.

3. Side edge grinding

The side edges, are precisely ground at an exactly defined angle (87°, 88° or 89°) and over the entire length. The specially developed sciolinamic bands are guided at a precisely defined angle over the unique sciolinamic glide shoe, the result for the side edge:

- Exact angle from the shovel to the end of the ski

- Excellent surface

- High lifetime of the sharpness

- Material-friendly removal

- High economy

4. Side edge tuning

In the unique MONTANA High Tech Tuning (HTT) system, the steel edge on the tread side is tuned slightly hanging at an angle of approximately 0.5°-0.8° and finely polished out. The burr that was created during grinding of the side edge is removed in the process. The specially developed tuning stones are dressed at a precisely defined angle with the dressing tool, the result for the edge:

- Exact angle from the shovel to the end of the ski

- Highly polished edge

- High service life of the sharpness

- Material-conserving removal

- High economy

In the unique RADIAL TUNING, the edge is tuned with approx. 0.5 ° in the binding area and 0.8 ° in the blade / end area suspended - without attacking the already optimized coating. The edge polished to a high gloss once again improves the gliding properties.

5. Waxing and polishing

Some MONTANA robots have an integrated waxing and polishing unit. Thus, no skinther finishing is required and the customer receives a ski that is ready to ride. For manual waxing and polishing, there are other MONTANA technologies.

How do the ski service robots prepare the side edges?

The side edge preparation is done with High Tech Ceramic tapes for even removal and an extremely fine finish. Ceramic glide shoes follow the geometry of the ski and adapt precisely to any radius. The special pressure curve ensures a precise edge angle over the entire length of the ski or board.

The pressure curve is also used for side edge processing. This enables particularly gentle processing from the beginning to the end of the ski, which is especially important for carving skis. The pressure curve makes it possible to achieve an outstanding finish with the smallest possible run-in marks while at the same time taking the ski geometry into account. With the new RACE EDGE finish system from MONTANA, the side edges receive the perfect racing grind. Two high-speed discs, which operate at speeds of up to 16,000 rpm, ensure a uniform grinding pattern.

The burr-free finish can be created with an angle adjustment in 0.5° increments. The function points of the ski are also optimized in this process. Programmable closing times and electronically controlled pressure curves for a precisely defined grinding pressure at the grinding point also take into account the geometry of different ski types. The absolutely burr-free and polished side edge delights all winter sports enthusiasts who have the highest demands.

What are VARIO structures?

The MONTANA VARIO structures allow different structure patterns across the width of the sports equipment.

The legendary MONTANA stone grinding ensures precisely cut structures. The most frequently used structures are stored in the software as VARIO structures by default.

The skis have damage and scratches in the running surface and glide poorly - What should I do?

Problem:

Pad damage affects rotatability and directional stability. Roughly and wavily ground pavements are slow. The lack of flatness causes uneven pressure distribution, resulting in poor sliding and turning.

Our recommendation:

- Repair the damage with P-Tex wire. The pavement should be free of fibers, flat and slightly textured. Flatness from edge to edge means optimal gliding and turning.

- Wax the skis regularly - this protects the ski running surfaces against oxidation by UV radiation.

My side edges slide jerkily. How do I fix this?

Problem:

Varying edge angles, rust, impact and wear prevent controlled edge use. An edge-to-edge hollow or convex sport tool produces uncontrollable edge grip and slides jerkily. Humpy or convex treads require extreme edging for edge grip and are unstable at increased speeds.

Our recommendation:

Edge geometry must be matched to snow conditions and skiing style. With an edge angle of less than 90°, you have better edge grip.

Plane running surfaces allow controlled turning. An important requirement for a good sports device is a minimum hanging edge (angle about 0.5 °) or even better: MONTANA Radial Tuning (angle 0.5 ° in the binding area and about 0.7 ° front and end). This way, the sports equipment turns easily and still allows rapid edge use. Ask your sports dealer for advice on ski service. For racing, more aggressive skiing, carving skis and hard slopes, ski service is highly recommended.

What does the Crystal Glide Finish seal say?

As a sign of special quality in ski and board service, the MONTANA CRYSTAL GLIDE FINISH quality seal vouches. The minimum requirement for the award of the quality seal is the use of a MONTANA stone grinding system and a MONTANA tuning system.

3 Step Promise: Surface - Edging - Tuning

MONTANA promises an optimally prepared sports equipment with impressive driving characteristics when using the three stages with MONTANA technology. For this, the interaction of all three stages is crucial.

A ski or board is only optimally prepared when the service steps in all processing stages from the base to the edges to the tuning are of consistently very good quality and high precision.

- Stage 1: A fiber-free, absolutely flat ground and structured running surface.

- Stage 2: Lateral edges that are precisely ground at a precisely defined angle (87°, 88° or 89°) and over the entire length.

- Stage 3: Absolutely smooth, tuned at an angle of about 0.5 ° - 0.8 °, tread side edges by Radial Tuning.

What makes MONTANA Radial tuning special?

Radial tuning

In this procedure, the skis are tuned more in the wider area, i.e. in the shovel and tail area, so that the edges hang more. In the binding area, less hanging is ground. This results in an edge angle that varies over the entire length of the ski, but is optimally adapted to the respective ski width.

Radial tuning makes skis and snowboards much easier to turn and, in particular, greatly improves the edge grip under the binding. The driver can break off the initiated turn in full swing with his sports equipment with radial tuning without the risk of falling.

What happens during MONTANA High Tech Tuning?

MONTANA High Tech Tuning (HTT)

In the unique MONTANA High Tech Tuning (HTT) system, the steel edge on the tread side is tuned slightly hanging at an angle of approx. 0.5°-0.8° and finely polished. The tuning stones specially developed for this purpose are dressed at a precisely defined angle with the dressing tool.

Tuning pressure curve

For particularly uniform tuning, the contact pressure can also be varied in 10 segments. It has proven to reduce the pressure, for example, in the binding area.

Ski rental & storage

What materials are the storage and deposit cabinets made of?

All storage systems are produced in Switzerland and only high quality materials are used with the application of the latest technologies. The shelves and their components are made of sendzimir galvanized and V2A steel. These are additionally powder-coated and are available in all RAL colors on request.

Thanks to the cathodic protection effect, the cut and punched edges are sustainably protected against corrosion. Thanks to the consistently applied honeycomb technology, the storage systems maintain their high stability and stability.

In the storage systems, your sports equipment comes out perfectly. The operation is designed according to the latest ergonomic findings and allows the fastest handling during input and output. Smooth-running, large rollers allow the racks to be moved with little force. They are unique in the world.

I would like to equip my store / ski rental with storage cabinets. What is the process?

For the economic success of a rental business and service workshop, professional planning of the entire process is of utmost importance. Based on our many years of experience, we plan the optimal solution for you.

Individual planning and design options

MONTANA supports you in all phases of project realization - from planning to implementation. For optimal utilization of space, we also create 3D visualizations on request, which make decision-making much easier. Of course, we also realize your individual color and labeling wishes.

Thus, the storage system can be harmoniously integrated into any existing store concept.

From now on, you also have the option of viewing your desired system in augmented reality (AR). Ask your consultant.

For whom are the depot systems suitable?

The depot systems provide comfortable storage and dry ski equipment in the ski depots of rental stations, mountain railroads, at private homes and in hotels.

But the lockers are also used in non-winter sports areas: fitness centers, swimming pools, schools as well as companies and institutions with (employee) lockers use our depot systems.

Take a look at our references and get inspired:

Skins

What material are MONTANA climbing skins made of?

Skin analysis

Fiber pile + base fabric

The skin pile is available in three different versions:

- 100% mohair

- Mohair Mix (65% mohair / 35% nylon)

- 100% synthetic (nylon)

During the weaving process, the skin pile is placed in one direction. This makes "climbing" and "sliding" possible in the first place. The skin pile is treated hydrophobic and remains permanently water-repellent.

Mohair is considered the name of the hair of the Angora goat. This natural fiber is the specific lightest fiber with unsurpassed properties for the production of climbing skins. 100% mohair climbing skins guarantee the best gliding and climbing properties. Mohair Mix offers a longer service life, as synthetic fibers are more abrasion-resistant.

MONTANA special

"MONTANA special" prevents lateral fraying when cutting the climbing skins.

Lamination

The waterproof laminate film is a reliable protective barrier against water ingress. This keeps the climbing skins dry even in wet snow.

Backing

The backing fabric is made of a blended fabric with polyester and cotton. It is firmly bonded to the base fabric via lamination. This type of bond keeps the climbing skin very flexible and supple even at low temperatures.

Adhesive layer

The specially developed MONTANA adhesive is applied to the backing fabric. For decades, resin adhesive has proven itself to be a reliable companion for any type of climb. The adhesive is particularly suitable for the new generation of rocker skis. Due to the high adhesive strength, the climbing skin remains securely on the ski even at low temperatures.

Non-glue-based: FUSIONTEC

As an easy and uncomplicated alternative, you can use the MONTAMIX ADRENALINE skin with our newly developed adhesion FUSIONTEC. This non-glue based adhesion is washable without losing adhesive strength. The fixation skin can be transported without a mesh cover or film and promises a residue-free and cold-resistant adhesive surface.

What is the difference between each coat quality?

- MONTARACE HIGH SPEED is made of 100 % mohair, is very light and fast. This natural product remains supple and soft even in very cold conditions and offers perfect grip when climbing due to the dense weave. MONTARACE in the sporty target flag design was developed specifically for racers, but can also be used by dedicated ski tourers:inside and ambitious recreational winter athletes:inside.

- MONTASPRINT is also made from the natural fiber mohair and leaves nothing to be desired in terms of gliding and climbing. On cold snow, it is particularly fast, since the skin surface corresponds to a fine structure and mohair by nature has a certain fat content.

- As a robust all-rounder is the climbing skin MONTAMIX made of a mixture of mohair and synthetic fiber. The nylon portion extends the life and leads to excellent climbing properties with a good glide in all temperature ranges.

- Who wants to be even more robust and cheaper on the road, relies on the pure synthetic fiber climbing skin MONTANYL. Thanks to the rather coarse structure, the MONTANYL climbing skin is fast on very wet snow.

Where can I buy MONTANA climbing skins?

MONTANA climbing skins we sell through sports retailers. Find a supplier near you on our map under Sales outlets: