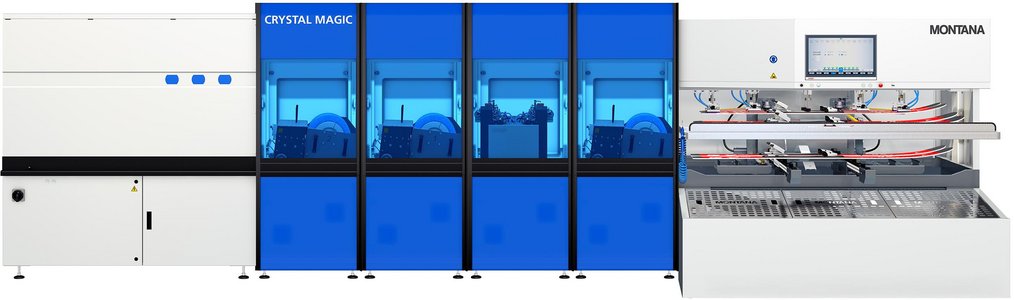

Automate the race service

The high quality of the grinding result of the CRYSTAL RACE is achieved by components specially developed for the race service. 3D High Tech Tuning (HTT) with PRO technology has been specially developed for the CRYSTAL RACE. This achieves an edge optimized for racing. All parameters for ski service are entered via a large display with intuitive operator guidance. A robot whose results inspire racing professionals.

The stone grinding with multiple VARIO structures is carried out in absolutely reproducible MONTANA quality. This results in perfect possibilities to optimally adapt the sliding properties to all conditions. For side edge grinding, the RACE EDGE aggregate is optionally available instead of the standard sciolinamic belt aggregate. On request, the CRYSTAL RACE can also be equipped with automatic loading.

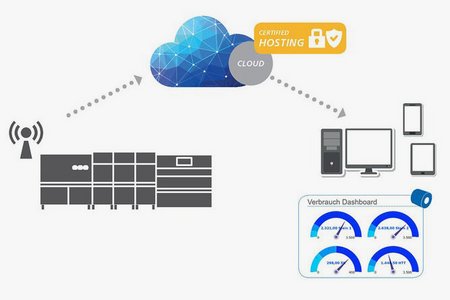

Skiservice robots from MONTANA are above-average in robustness, quality and durability. The machines are equipped with stable, easy-to-use software that allows you, among other things, to create, grind and adjust your desired structures over and over again. Our tested VARIO structures are already integrated.

Each service robot also grinds cross-country skis. High performance, low consumable costs and sustainable technology promise a long service life as well as a high resale value.

Options

- 3D structures

- Pair loading

- Compressor with refrigeration dryer

- RACE EDGE unit

- Oil mist-Extraction

- Gravity filter system

- Automatic cooler

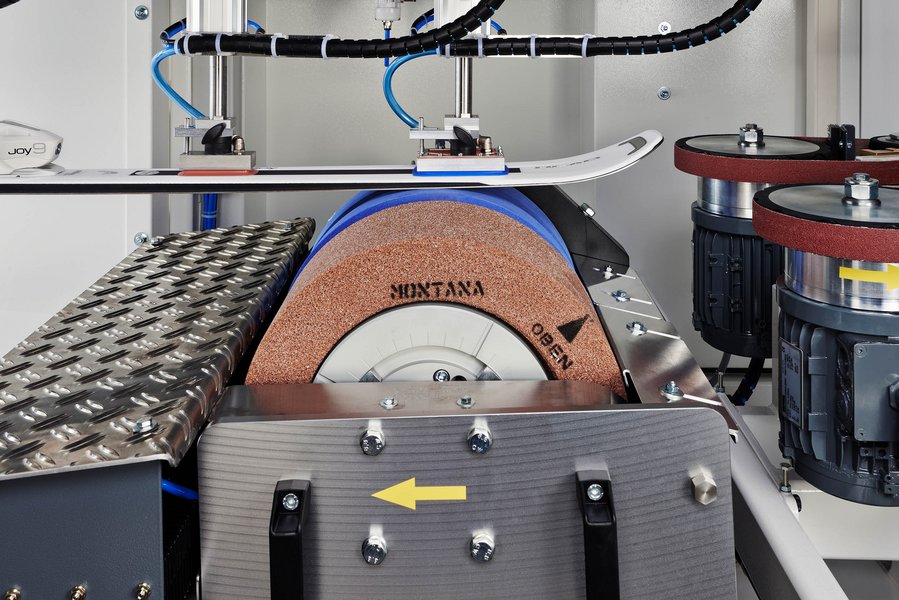

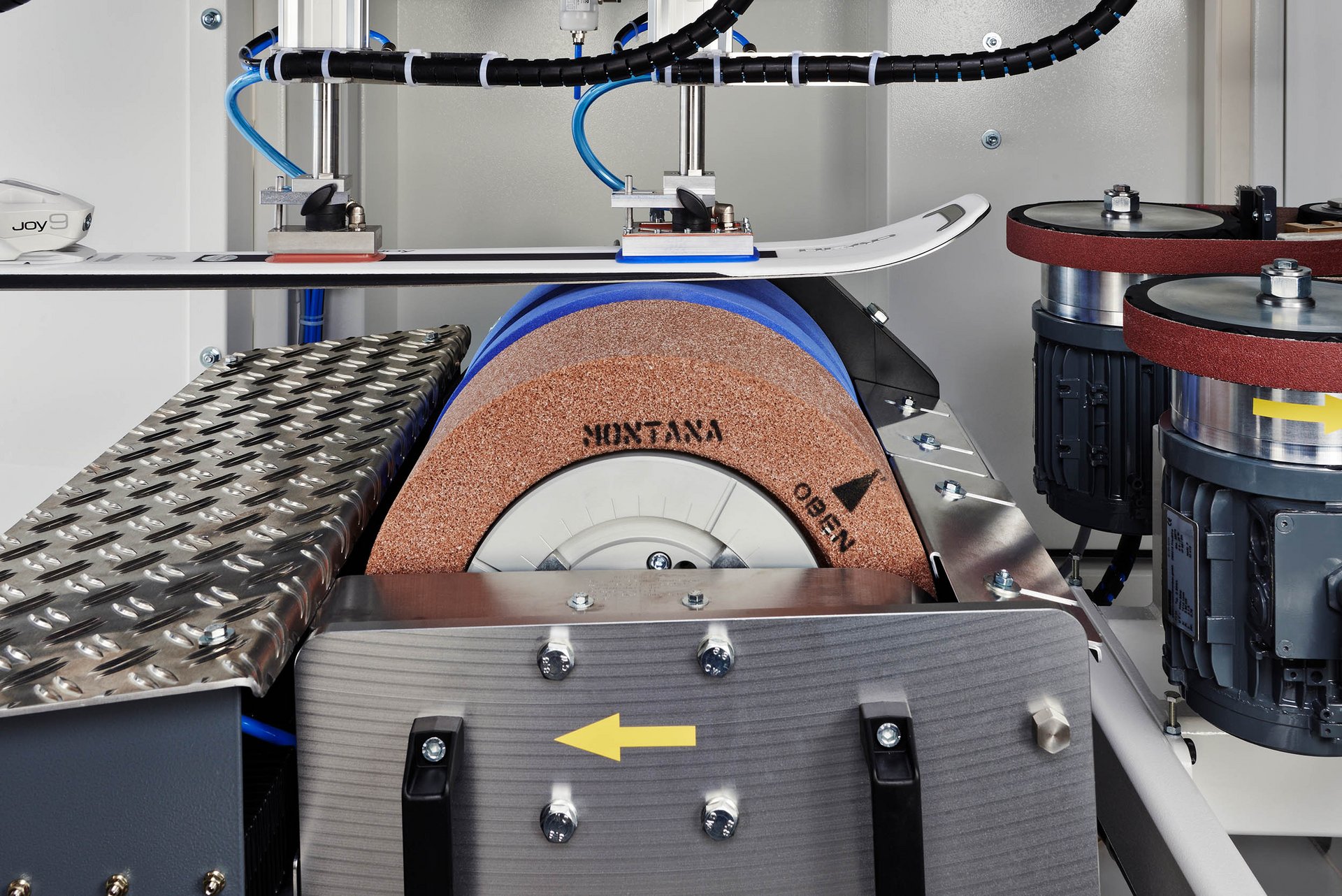

PRO technology for stone grinding

With MONTANA PRO technology, the ski receives a stone grinding, which controls the grinding process even finer and according to the ski geometry. For this purpose, the contact pressure on the running surface is individually controlled both from above and from below by a high-precision pressure curve for each grinding stone. With the PRO technology, the harmonic movement, which one also has when skiing, is taken into the grinding: The ski glides over the stone as if skiing over a hill. Likewise, the grinding of the shovel and ski end is possible in this way.

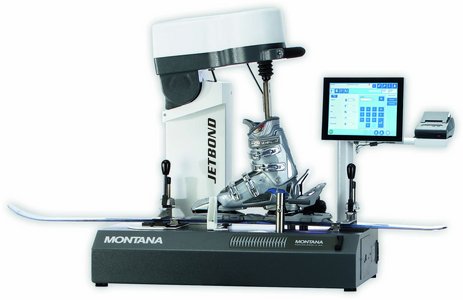

Side edge grinding with GRIPtech

The grinding in the vertical direction creates a particularly advantageous sharpness and edge geometry (microstructure). GRIPtech ensures a precise, sharp and above all durable edge

Radial tuning

The MONTANA Radial tuning makes the skis much more rotatable - especially the edge grip under the binding is thus even better. So that the edges hang off more, the skis are tuned more in the wider area, i.e. in the shovel and tail area. In the binding area, the tuning is done at a lower angle. This results in a perfect edge angle that is adapted to the curve.

Ski service for professional sports

Automate race service with a range of specially developed components. 8-fold VARIO structures, 3D Radial Tuning and PRO technology make the highly accurate grinding result absolutely reproducible.

Advantages

- Large touch display with intuitive navigation

- PRO technology for particularly gentle grinding even in the shovel and end area

- PowerVac system for suction of all ski surfaces

- Automatic stone grinding for 1 ski with pressure curve and computer-controlled speed-Curve

- multiple VARIO structures

- Double sided edge grinding with pressure curve

- 3D High Tech Tuning (HTT) of edges

- Free programmable Radial Tuning

- NC controlled servo motors for dresser drive, Dresser infeed and carriage

- Integrated remote maintenance

- High precision pressure curve for the latest ski models. By NC - technology separately for each stone individually and finely adjustable.

- Twin Tip grinding of shovel and ski end possible

- NC - controlled dresser feed via stepper motors for grinding and tuning stones. This allows for even more precise dressing.

Technical data

CRYSTAL RACE - manual loading

| Power: | max. 7 kW |

| Voltage: | 3 x 400 volts / 50/60 Hz, special voltage via transformer |

| Fuse: | 3 x 16 A |

| Stone width: | 200 mm |

| Stone speed: | 300 - 1'900 rpm |

| Cutting speed: | 6 - 32 m/s |

| Compressed air: | min. 6 bar, 600 l/min |

| Total weight: | 1,950 kg excl. emulsion |

CRYSTAL RACE Max - automatic loading

| Power: | max. 8 kW |

| Voltage: | 3 x 400 volts / 50/60 Hz, special voltage via transformer |

| Fuse: | 3 x 30 A |

| Stone width: | 200 mm |

| Stone speed: | 300 - 1'900 rpm |

| Cutting speed: | 6 - 32 m/s |

| Compressed air: | min. 6 bar, 1,100 l/min |

| Total weight: | 2,100 kg excl. emulsion |

Dimensions

| Length: | 5,740 mm |

| Width: | 1,665 mm |

| Height: | 1,998 mm |