Fusing and repair

Layers of skis and snowboards can be completely melted and repaired with this machine in a single operation and without templates. The P-TEX SPEEDMASTER II is enormously powerful. With low material consumption, it achieves a perfect melting result. An ingenious loading system and the avoidance of idle times achieve the output of >60 pairs of skis in one run. Due to the split head, the winter sports equipment adapts better regardless of the insertion position. Thus, for example, curved snowboards can be processed better.

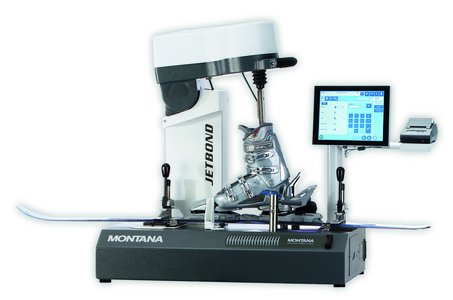

MONTANA also offers a solution for every workshop size in manual ski service machines. From stone grinding and side edge processing with tuning to waxing and polishing, MONTANA technology ensures full customer satisfaction and excellent skiing pleasure. Bela repair is the first step in professional snowboard and ski service. MONTANA offers different solutions for this depending on the requirements: from the manual melting device MONTY EXTRUDER to the compact melting robot MRS 180 to the P-TEX melting systems with automated sequence.

Perfect melting results

The P-TEX SPEEDMASTER II is extremely powerful. It melts and repairs ski and snowboard bases with low material consumption

Advantages

- Preheating of the winter sports equipment with infrared lamp

- Loading with swivel technology to avoid downtime

- Melting speed, material supply and compression pressure infinitely variable

- Surface-friendly melting temperatures

- Integrated fume extraction with fan

- Positive melting for best repair results

- 4-fold wire feed

- Easy operation via touch panel

- Selectable programs for ski and board allow easy processing

Technical data

Machine

| Power: | 8.3 kW |

| Voltage: | 3 x 400 volts, special voltage via transformer |

| Fuse protection: | 3 x 16 A |

| Compressed air: | min. 6 bar, 50 l/min |

| Total weight: | 480 kg |

Decided already?

Then contact us for skinther steps. If not, our service team will be happy to advise you.