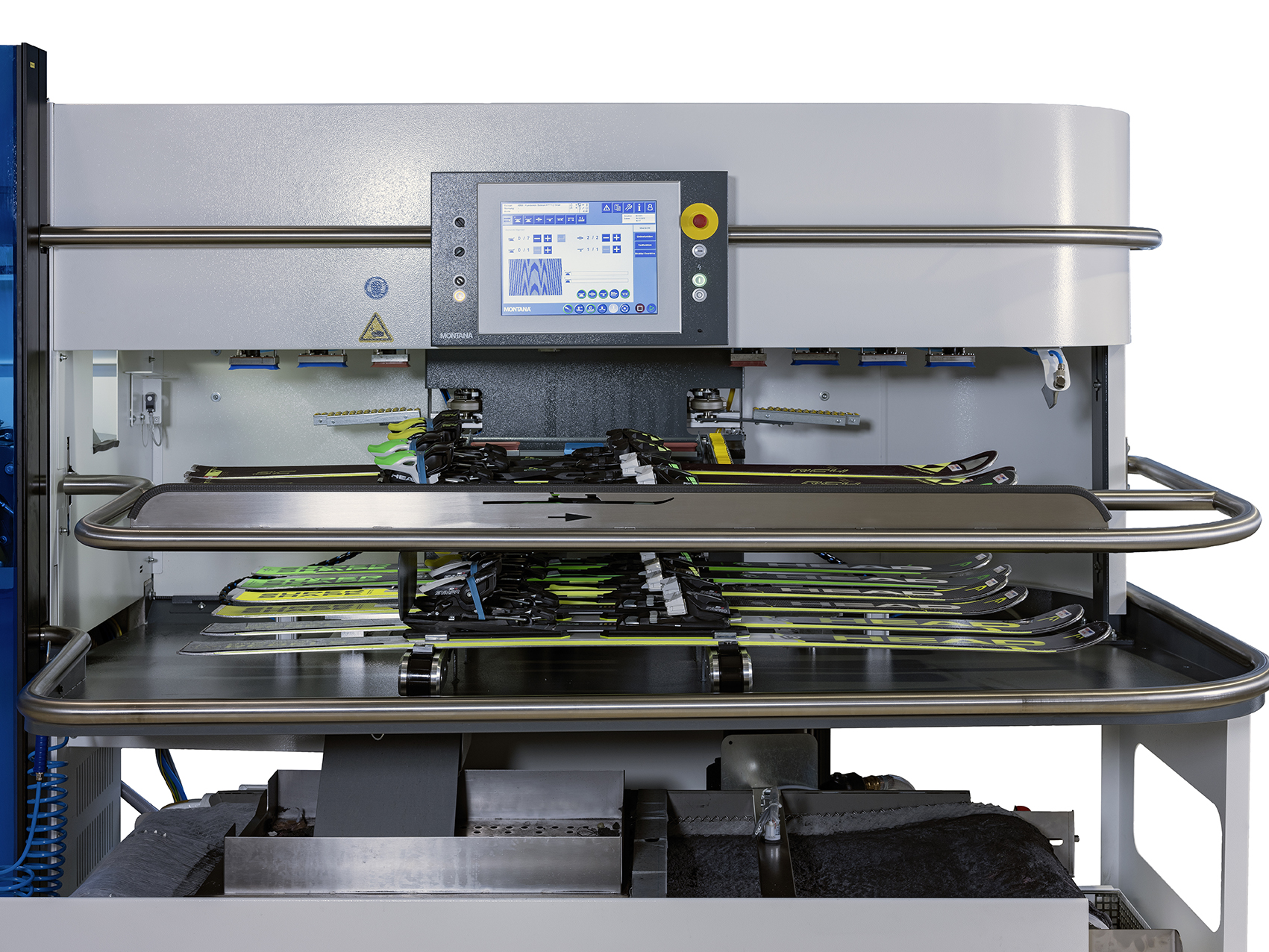

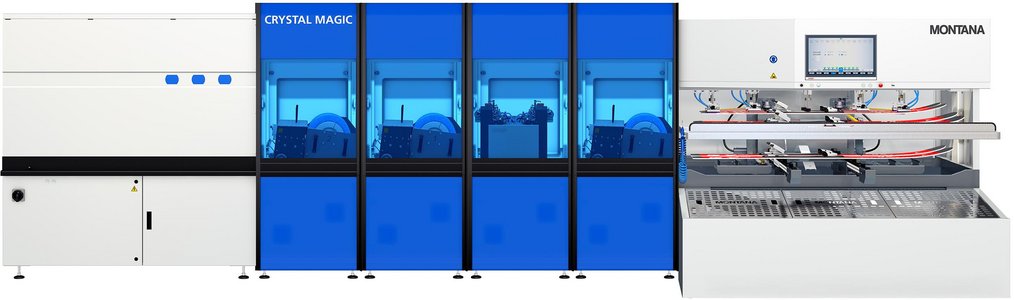

For pure ski service with high service volume

With two grinding stones, the CRYSTAL ONYX service robot is the perfect machine for this: 50 pairs of skis per hour with 4 stone contacts ensure an effective process.

The service sequence is fully automatic with machine measurement of the ski length - so the suction system with 7 plates adapts to the ski geometry, ensuring fast and safe work. With the integrated PRO technology, all ski models including Rocker and Twin Tip are perfectly planar ground and structured at the shovel and ski end. Then our revolutionary GRIPtech system grinds the side edges in RACE EDGE quality: creating a precise, sharp and durable edge. In addition to radial tuning, 3D High Tech Tuning (HTT) with PRO technology opens up entirely new tuning options. For the finish, the ski is automatically waxed and polished. The CRYSTAL ONYX with 2 stones and waxing unit combines high throughput with the best service quality.

Ski service robots from MONTANA are above average robust, high quality and durable. The machines are equipped with stable, easy-to-use software that allows you, among other things, to create, grind and adjust your desired structures over and over again. Our tested VARIO structures are already integrated. High performance, low consumable costs and sustainable technology promise a long service life as well as a high resale value. Due to the fully automatic process of the CRYSTAL ONYX ski service robot, the service is particularly precise. Every MONTANA service robot also grinds cross-country skis.

PRO technology for double stone grinding

First, the ski receives a stone grinding with MONTANA PRO technology, which controls the grinding process even more finely and according to the ski geometry. For this purpose, the contact pressure on the running surface is individually controlled from above as well as from below by a highly precise pressure curve for each grinding stone. By using 2 stones with different grit sizes, excellent structural results are produced while at the same time ensuring gentle processing. It is also possible to grind the shovel and the end of the ski. With the PRO technology, the harmonic movement that you have when skiing is also taken into the grinding: The ski glides over the stone as if skiing over a hill.

Side edge preparation with the GRIPtech system

GRIPtech is the revolution in the preparation of the side edge: so a precise edge is produced. This process grinds all functional points from the shovel to the end of the ski with a precise angle in RACE EDGE quality. The result is maximum service life of the sharpening, combined with material-friendly abrasion. The unique feature: the grinding in the vertical direction creates microstructures that result in a sharp and durable edge.

Surface-side radial tuning

With the MONTANA radial tuning, the skis become much more turn-friendly - in particular, the edge grip under the binding is thus even better. So that the edges hang off more, the skis are tuned more in the wider area, i.e. in the shovel and tail area. In the binding area, the tuning is done at a lower angle. This results in a perfect edge angle that is adapted to the curve.

High End Ski Service

The CRYSTAL ONYX service robot is the optimal machine for pure ski service in rental stations and workshops with a high servicevolume

Advantages

- High throughput: 50 pairs of skis per hour with 4 stone contacts

- Large touch display with intuitive navigation

- Automatic length detection

- PowerVac system for suctioning all ski surfaces

- Automatic stone grinding with pressure and force curve

- PRO technology for especially gentle grinding even in the shovel and end area

- GRIPtech for sideedge preparation in RACE EDGE quality

- Exact and evenmoderate angle

- Gentle material removal

- Grinds even corrod edges protprotruding

- Surface side high tech tuning of edges with power curve and 350 mm tuning stone

- 3D tuning for radial tuning and variable adjustable tuning angles

- NC controlled servo motors for carriage

- Waxing and polishing unit

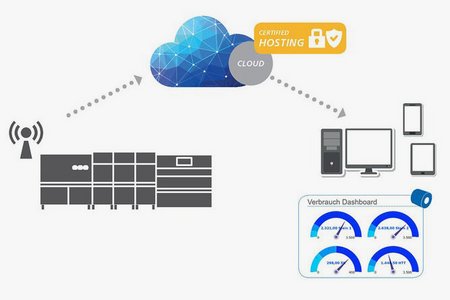

- Integrated remote maintenance

Technical data

Machine

| Power: | max. 17.3 kW |

| Voltage: | 3 x 400 volts / 50/60 Hz, special voltage via transformer |

| Fuse: | 3 x 30 A |

| Stone width: | 180 mm | Steel speed: | 300 - 1.900 rpm |

| Cutting speed: | 6 - 32 m/s |

| Feed: | 5 - 30 m/min |

| Compressed air: | min. 6 bar, 1,100 l/min |

| Total weight: | 3,900 kg incl. emulsion |

Dimensions

| Length: | 7,997 mm |

| Width: | 1,796 mm |

| Height: | 2,047 mm |